AI-Native Machine Health Monitoring for Industrial Equipment

Route42's plug-and-play solution gives manufacturers the heads up on machine health before failures happen

Route42's plug-and-play solution gives manufacturers the heads up on machine health before failures happen

Stop waiting months for complex implementations. Our plug-and-play solution gets you up and running in 24 hours, no technical expertise needed, and scales from one machine to hundreds.

Learn more

Get instant, operator-friendly root cause analysis without vibration analysis experts. Your team receives clear maintenance recommendations in a language they understand.

Learn more

No more alert fatigue or wasted time chasing false positives. Our Alert Validation System delivers only significant alerts with proven impact, ensuring focus on real production issues.

Learn more

Gather machine information, mount sensor, connect pre-configured gateway

Stream data to cloud, establish baseline, AI learns & alert validation starts

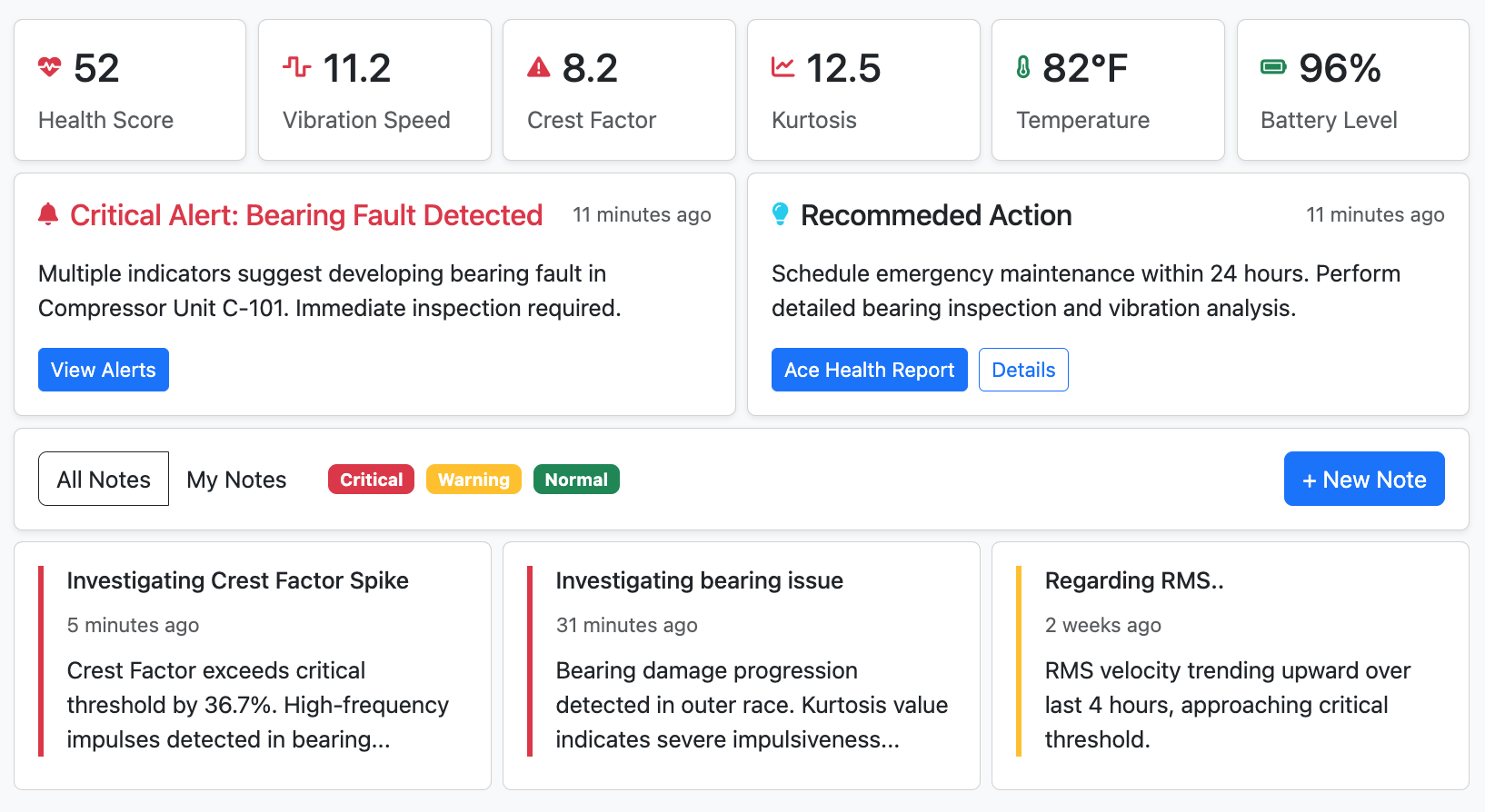

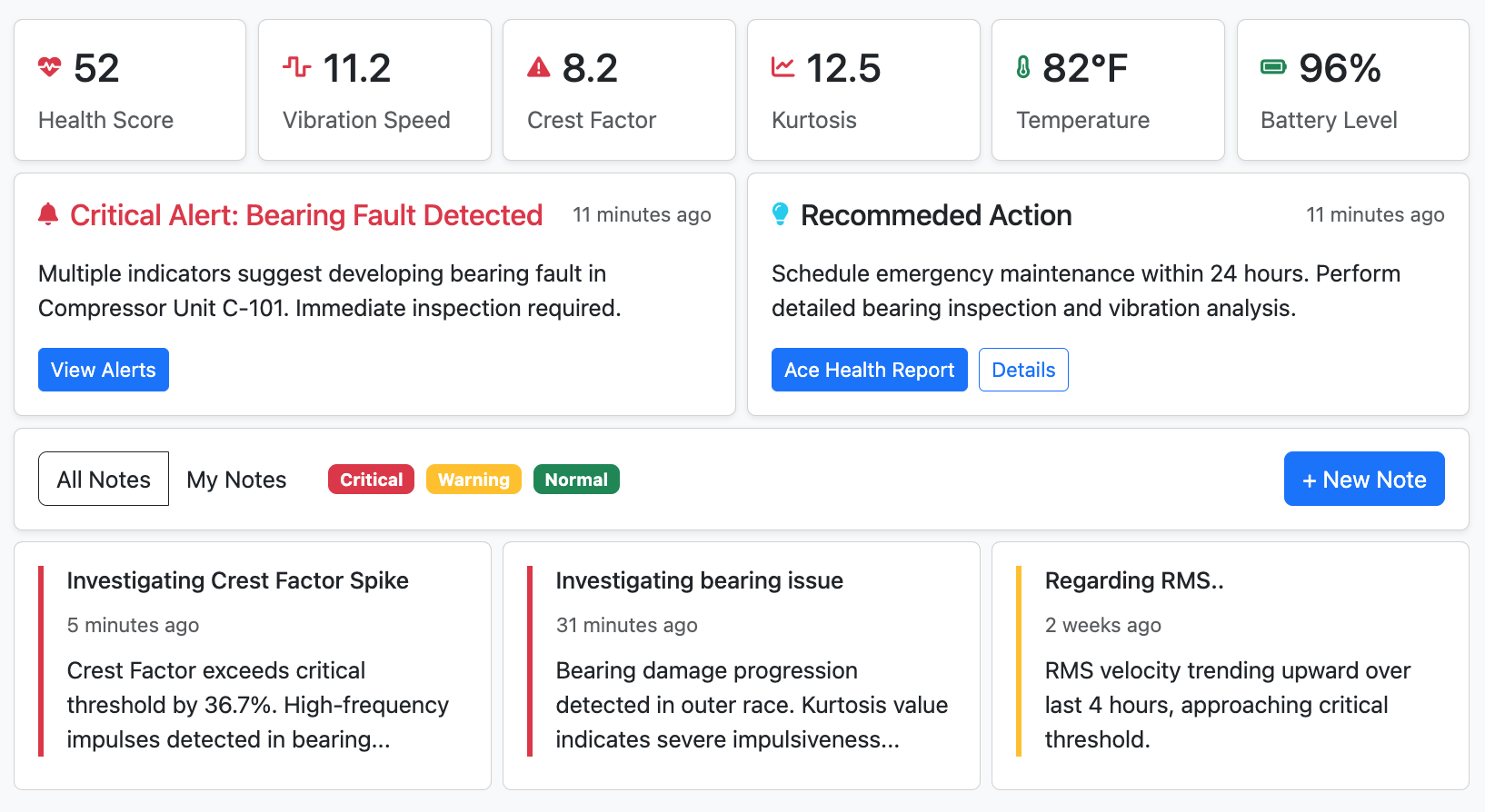

Real-time health metrics, validated alerts, root cause analysis, and health reports

Predict and prevent equipment issues before they impact your operations

Monitor performance metrics and receive actionable recommendations

Get notified of potential issues before they become problems

Start optimizing your operations with minimal upfront investment

Achieve significant cost savings through predictive maintenance

Access powerful analytics with zero learning curve

Magnetically mount, connect, and transform your factory floor – without disrupting production.

AI-powered guidance that turns your operators into advanced tech experts in real time.

Direct connection to SAP maintenance workflows through certified integration partners.

Praxie - Official member of the SAP® PartnerEdge® Open Ecosystem

Praxie's AI-Powered Digital Transformation platform digitizes your business 10x faster at one-tenth the cost, automating processes with pre-configured applications that transform your organization in days, not months.

Wear, misalignment, and lubrication problems

Uneven mass distribution in rotating equipment

Offset and angular errors between coupled shafts

Mechanical play in components and mountings

Wear, cracking, and mesh alignment issues

Harmful vibrations at system natural frequencies

Rotor, stator, and magnetic field abnormalities

Bubble formation and collapse in fluid systems

Join forward-thinking manufacturers in achieving operational excellence through intelligent automation.